Global Directory

- Anguilla - English

- Antigua & Barbuda - English

- Aruba - English

- Bahamas - English

- Barbados - English

- British Virgin Islands - English

- Cayman - Islands - English

- Curacao - English

- Dominica - English

- Dominican Republic - Español

- Grenada - English

- Guadeloupe - English

- Haiti - English

- Jamaica - English

- Martinique - English

- Puerto Rico - English

- Puerto Rico - Español

- Saint Barthélemy - English

- Saint Kitts and Nevis - English

- Saint Lucia - English

- Saint Martin - English

- Saint Vincent & The Grenadines - English

- Trinidad & Tobago - English

- Virgin Islands - English

- Austria - Deutsch

- Belgium - Français

- Belgium - Nederlands

- Bosnia & Herzegovina - English*

- Bulgaria - English*

- Croatia - English*

- Czech Republic - Čeština

- Denmark - Dansk

- Finland - Suomeksi

- France - Français

- Germany - Deutsch

- Greece - English

- Hungary - Magyarország

- Ireland - English

- Italy - Italiano

- Macedonia - English

- Netherlands - Dutch

- Norway - Norge

- Poland - Polski

- Portugal - Português*

- Romania - Romanian

- Russia - Русский

- Serbia - English

- Slovakia - Slovenčina

- Spain - Espanol

- Sweden - Swedish

- Switzerland - Deutsch*

- Switzerland - Français*

- Switzerland - Italiano*

- United Kingdom - English

Global Directory

- Anguilla - English

- Antigua & Barbuda - English

- Aruba - English

- Bahamas - English

- Barbados - English

- British Virgin Islands - English

- Cayman - Islands - English

- Curacao - English

- Dominica - English

- Dominican Republic - Español

- Grenada - English

- Guadeloupe - English

- Haiti - English

- Jamaica - English

- Martinique - English

- Puerto Rico - English

- Puerto Rico - Español

- Saint Barthélemy - English

- Saint Kitts and Nevis - English

- Saint Lucia - English

- Saint Martin - English

- Saint Vincent & The Grenadines - English

- Trinidad & Tobago - English

- Virgin Islands - English

- Austria - Deutsch

- Belgium - Français

- Belgium - Nederlands

- Bosnia & Herzegovina - English*

- Bulgaria - English*

- Croatia - English*

- Czech Republic - Čeština

- Denmark - Dansk

- Finland - Suomeksi

- France - Français

- Germany - Deutsch

- Greece - English

- Hungary - Magyarország

- Ireland - English

- Italy - Italiano

- Macedonia - English

- Netherlands - Dutch

- Norway - Norge

- Poland - Polski

- Portugal - Português*

- Romania - Romanian

- Russia - Русский

- Serbia - English

- Slovakia - Slovenčina

- Spain - Espanol

- Sweden - Swedish

- Switzerland - Deutsch*

- Switzerland - Français*

- Switzerland - Italiano*

- United Kingdom - English

Maximize your efficiency by optimizing your speed with YORK® VSD

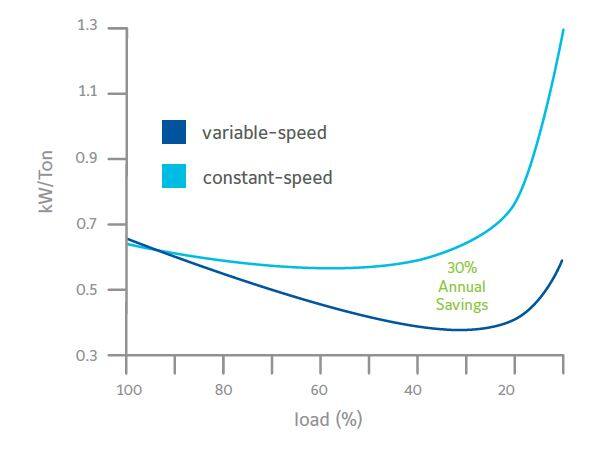

Variable speed drives (VSDs) can cut a chiller’s annual energy use by up to 30 percent while maintaining operating reliably over a wide range of condition. This is accomplished in two ways:

- At part load when cooling capacity can be reduced, a VSD chiller inherently uses less energy than a constant speed chiller whenever the compressor speed can be reduced to more closely match the load.

- At low-lift conditions, when ambient temperature conditions are cooler than design, or chilled water reset is used, or both, up to four times more energy can be saved if the VSD chiller is designed to operate in these off-design conditions.

By accruing off-design energy savings during nearly 99% of your chiller’s operating season, the payback for a YORK VSD can come in as little as one to three years. Plus you’ll realize substantial energy savings, month after month and year after year, over the life of the chiller.

Additional YORK VSD cost savings? YES!

- Reduces auxiliary-component costs. Its high power factor eliminates the need for a power-factor-correction capacitor.

- Offers ability to specify a smaller generator

- Requires 60% lower start-up amps.

- Serviceable onsite, reducing downtime

- Better electrical protection – never draws more than 100% of its full-load amps.

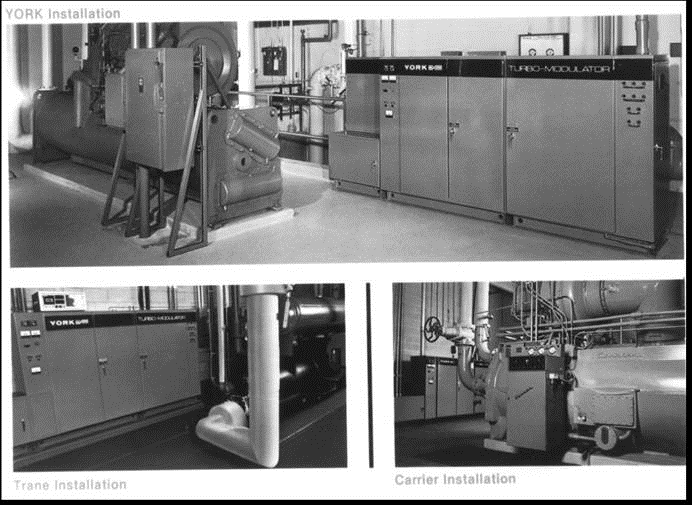

The YORK VSD was specifically developed for commercial air conditioning applications. Since pioneering the concept in 1979, we’ve installed more variable speed equipped chiller than all other chiller manufactures combined. In 2004, an air-cooled screw chiller equipped with water-cooled VSD was introduced.

In 2005 Johnson Controls received the Climate Protection Award from the U.S. Environmental Protection Agency (EPA). The award recognizes the pioneering work and ongoing development of electronic variable-speed-drive (VSD) technology and its dramatic energy-saving capability when applied to chillers.

And not only does Johnson Controls offer the most experience of any manufacturer, but also the widest application range. The success of our VSDs is not based just on theoretical test findings, but real-world conditions.

Learn more about the history of VSDs and centrifugal compressors by downloading this article from the YORK archives.

Chillers can account for 35 percent of HVAC energy use in many commercial buildings, but today’s Variable Speed Drives (VSDs) can cut a chiller’s annual energy cost by 30 percent or more. Learn more about how VSDs can optimize energy use at full and part load, as well as under off-design conditions in this one-hour free webcast.